Blog

By Northfork Precision

•

May 9, 2020

Choosing a CNC machine shop means looking for a company that has the right set up with the right capabilities for your project. The machine shop you choose will need to have the talent and the equipment to be able to keep up with your needs. Knowing what questions to ask when you first make contact will help you choose the right CNC machine shop for your company's individual needs. Are The CNC Operators Experienced? One of the most important questions you will need to ask is whether or not their CNC operators have the experience of making the products or components you need. For example, North Fork Precision has specialty experience with precision machining to create specialized components for the electronics, medical devices, and imaging industries. Having specialized CNC experience means that the operators know what they are doing and have the skills to deliver the end product to the highest standards of the industry. It also ensures that whatever work is completed in the shop will meet or exceed the expectations of both their supervisors and your quality control team. Does the Shop Have Reviews or References? Another important question to ask is whether or not the shop has references. Ask for the names and phone numbers of other companies they have worked for. Is the shop recommended by your peers or other companies that require the services of a CNC shop? Ask around. Word of mouth is often the best form of advertising. North Fork Precision is happy to provide references and reviews for new customers considering us for their next precision CNC project. What Types of Processes Do They Use? CNC machine shops use a variety of processes. Each process is used to achieve a different result. The processes and methods will depend on what materials are being used and whether a smooth or rough surface is required. It's essential that you know what processes and materials you require for your project, and that you express those needs with your potential supplier. The processes and methods are different for each type of material being used and can make for substantial changes in price. We are currently working to develop an ISO standard operating procedure that will certify our quality standards. Do They Offer High-Quality Work on a Consistent Basis? If you are offered a list of references, make sure to inquire about the shop's consistency when it comes to providing high-quality work on a regular basis. Are they capable of producing the level of quality you need with each order they complete for you? Asking prior customers is the best way to get an answer to this question. Are They Capable of Doing the Type and Amount of Work You Require? The next questions have to do with both the type of work they do and whether or not they can accommodate the amount of work you need. Are they capable of mass-producing an item or do they primarily offer customized work? If you need a large number of specially made parts, a smaller CNC machine shop may not have the capability to accommodate your request. Before you hire a CNC machine shop to do your work, make sure all of your questions are answered. It's also important to make sure the operators know exactly what you expect from them in terms of deadline and quality. Go the extra mile and find out as much as you can prior to hiring them. This will ensure you are satisfied with their work and there won't be any surprises later on. At North Fork Precision, we welcome your inquiry into our experience, capabilities, and dedication to deliver high quality, production quantity precision CNC work, on time, every time. Request a Quote today to learn more about how we can help you with your next CNC project.

December 4, 2019

North Fork Precision is a small CNC machine shop proudly producing parts that are made in the USA from our location in Bozeman, MT. We have a customer driven focus and commitment to on-time delivery of top-quality products. The team at North Fork Precision takes pride in being reliable, accurate and prompt. Our customers’ success is our number one priority, which is why we do everything we can to meet the demands or challenges involved in the sourcing of precision machined parts. Our approach to CNC work and contract manufacturing creates long-term relationships with our customers highlighted by our customized service that exceeds expectations year after year. Company History In 2017, North Fork Precision purchased JTech Precision Machining. Previous owner, Jay Cowan, started JTech Precision in the Gallatin Valley in 2002 and North Fork Precision continues to build upon their reputation for on-time delivery and quality products. Substantial growth over the past few years is a testament to the trust our customers have placed in our services. Prior to starting North Fork Precision in 2017, Owner Kyle Copelan worked for an aerospace facility producing high-strength steel landing gear components for the Department of Defense. While working at this facility he developed skills and techniques, not only in machining parts but also in quality control and precision measuring. He found that documentation and traceability were a crucial component of the job. Company Outlook North Fork Precision’s Quality Manual is an ongoing work in progress that will result in the achievement of the ISO 9001:2015 certification to better serve the quality standards that our customers demand. At North Fork Precision, our passion is focused on manufacturing and the economic impact manufacturing can provide to our community, and to our country. By providing quality manufacturing services, we are able to help stimulate the local economy. This is an impact we are truly proud of. In addition to employing talent, North Fork Precision works to educate younger generations in the value of manufacturing and career potential in the manufacturing industry. As manufacturing automation increases with technology advancement, we educate the future manufacturing workforce about the increasing need for workers with advanced skills to ensure that these automated processes run smoothly. North Fork Precision has plans on focused investment in advanced manufacturing technology in the coming years while moving toward automated processes and an ever advancing workforce. We’re dedicated to employing the technology and talent necessary to produce our customers’ parts with shorter lead times, higher quality, and with more efficiency to compete on a global level.

April 15, 2019

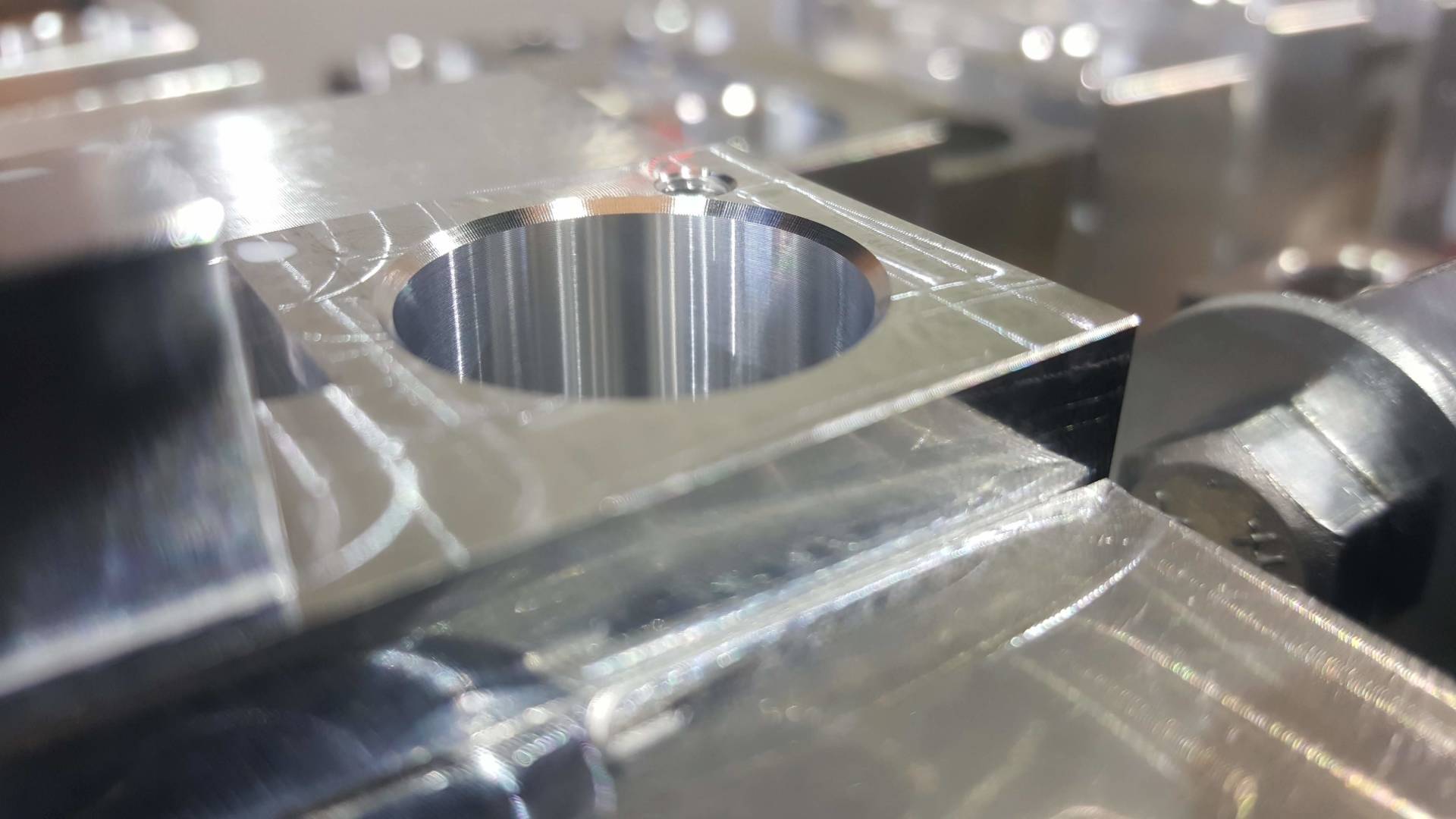

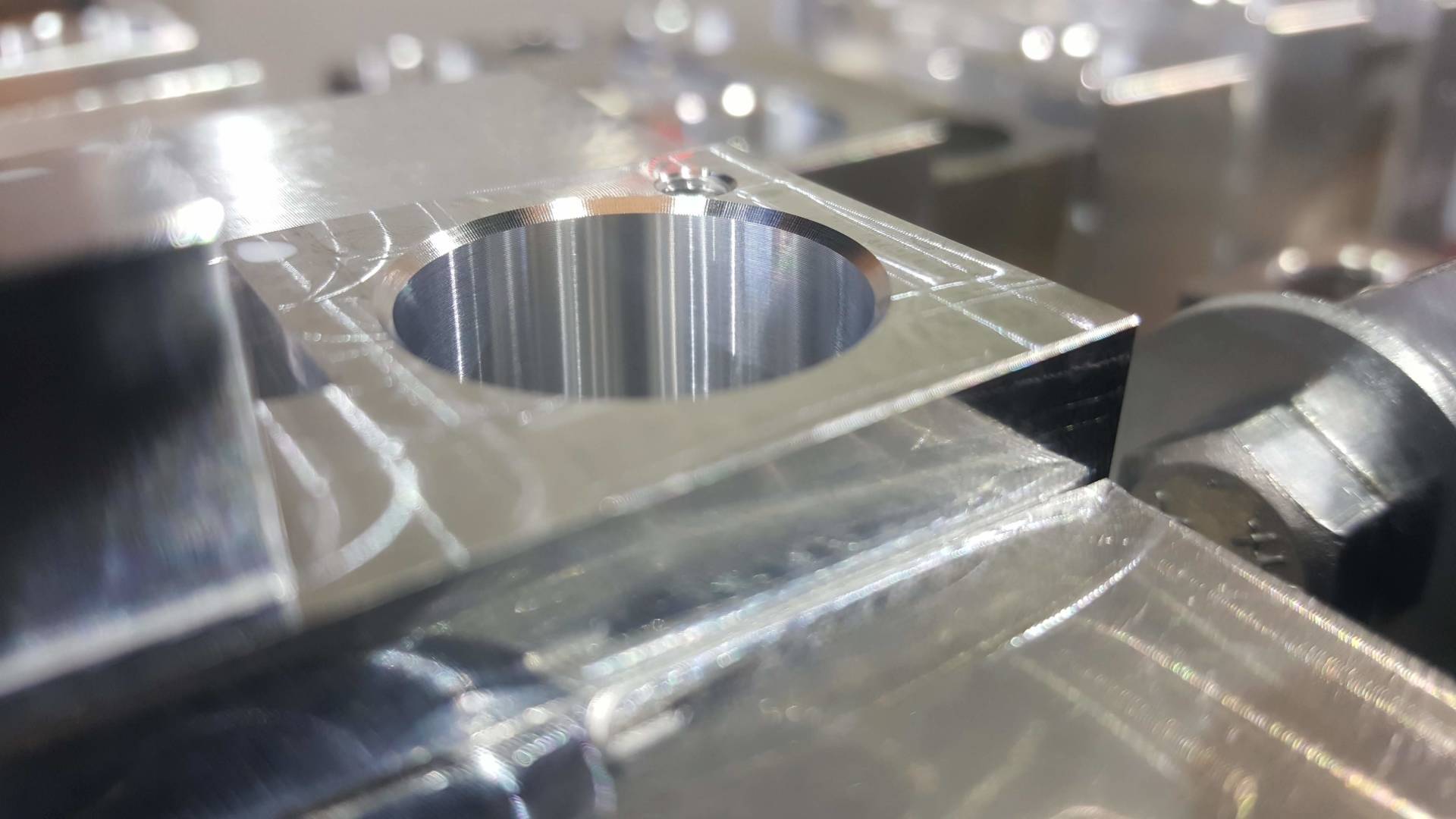

High performance, fast rapids, quick tools changes, and high volume are all words that come to mind when we talk about why we love the Haas Super-Speed Vertical Machining Center. With a 12,000 rpm direct drive, inline spindle and an ultra-fast side mount tool changer, we can deliver high volume, precision CNC manufacturing for our clients in specialized industries like photonics, labs, imaging, and electronics. Haas VF-4SS Highlights: High-speed spindle Fast rapids Super-speed side-mount tool changer More X- and Z-axis travel Made in the USA

CNC Blog

By Northfork Precision

•

May 9, 2020

Choosing a CNC machine shop means looking for a company that has the right set up with the right capabilities for your project. The machine shop you choose will need to have the talent and the equipment to be able to keep up with your needs. Knowing what questions to ask when you first make contact will help you choose the right CNC machine shop for your company's individual needs. Are The CNC Operators Experienced? One of the most important questions you will need to ask is whether or not their CNC operators have the experience of making the products or components you need. For example, North Fork Precision has specialty experience with precision machining to create specialized components for the electronics, medical devices, and imaging industries. Having specialized CNC experience means that the operators know what they are doing and have the skills to deliver the end product to the highest standards of the industry. It also ensures that whatever work is completed in the shop will meet or exceed the expectations of both their supervisors and your quality control team. Does the Shop Have Reviews or References? Another important question to ask is whether or not the shop has references. Ask for the names and phone numbers of other companies they have worked for. Is the shop recommended by your peers or other companies that require the services of a CNC shop? Ask around. Word of mouth is often the best form of advertising. North Fork Precision is happy to provide references and reviews for new customers considering us for their next precision CNC project. What Types of Processes Do They Use? CNC machine shops use a variety of processes. Each process is used to achieve a different result. The processes and methods will depend on what materials are being used and whether a smooth or rough surface is required. It's essential that you know what processes and materials you require for your project, and that you express those needs with your potential supplier. The processes and methods are different for each type of material being used and can make for substantial changes in price. We are currently working to develop an ISO standard operating procedure that will certify our quality standards. Do They Offer High-Quality Work on a Consistent Basis? If you are offered a list of references, make sure to inquire about the shop's consistency when it comes to providing high-quality work on a regular basis. Are they capable of producing the level of quality you need with each order they complete for you? Asking prior customers is the best way to get an answer to this question. Are They Capable of Doing the Type and Amount of Work You Require? The next questions have to do with both the type of work they do and whether or not they can accommodate the amount of work you need. Are they capable of mass-producing an item or do they primarily offer customized work? If you need a large number of specially made parts, a smaller CNC machine shop may not have the capability to accommodate your request. Before you hire a CNC machine shop to do your work, make sure all of your questions are answered. It's also important to make sure the operators know exactly what you expect from them in terms of deadline and quality. Go the extra mile and find out as much as you can prior to hiring them. This will ensure you are satisfied with their work and there won't be any surprises later on. At North Fork Precision, we welcome your inquiry into our experience, capabilities, and dedication to deliver high quality, production quantity precision CNC work, on time, every time. Request a Quote today to learn more about how we can help you with your next CNC project.

December 4, 2019

North Fork Precision is a small CNC machine shop proudly producing parts that are made in the USA from our location in Bozeman, MT. We have a customer driven focus and commitment to on-time delivery of top-quality products. The team at North Fork Precision takes pride in being reliable, accurate and prompt. Our customers’ success is our number one priority, which is why we do everything we can to meet the demands or challenges involved in the sourcing of precision machined parts. Our approach to CNC work and contract manufacturing creates long-term relationships with our customers highlighted by our customized service that exceeds expectations year after year. Company History In 2017, North Fork Precision purchased JTech Precision Machining. Previous owner, Jay Cowan, started JTech Precision in the Gallatin Valley in 2002 and North Fork Precision continues to build upon their reputation for on-time delivery and quality products. Substantial growth over the past few years is a testament to the trust our customers have placed in our services. Prior to starting North Fork Precision in 2017, Owner Kyle Copelan worked for an aerospace facility producing high-strength steel landing gear components for the Department of Defense. While working at this facility he developed skills and techniques, not only in machining parts but also in quality control and precision measuring. He found that documentation and traceability were a crucial component of the job. Company Outlook North Fork Precision’s Quality Manual is an ongoing work in progress that will result in the achievement of the ISO 9001:2015 certification to better serve the quality standards that our customers demand. At North Fork Precision, our passion is focused on manufacturing and the economic impact manufacturing can provide to our community, and to our country. By providing quality manufacturing services, we are able to help stimulate the local economy. This is an impact we are truly proud of. In addition to employing talent, North Fork Precision works to educate younger generations in the value of manufacturing and career potential in the manufacturing industry. As manufacturing automation increases with technology advancement, we educate the future manufacturing workforce about the increasing need for workers with advanced skills to ensure that these automated processes run smoothly. North Fork Precision has plans on focused investment in advanced manufacturing technology in the coming years while moving toward automated processes and an ever advancing workforce. We’re dedicated to employing the technology and talent necessary to produce our customers’ parts with shorter lead times, higher quality, and with more efficiency to compete on a global level.

April 15, 2019

High performance, fast rapids, quick tools changes, and high volume are all words that come to mind when we talk about why we love the Haas Super-Speed Vertical Machining Center. With a 12,000 rpm direct drive, inline spindle and an ultra-fast side mount tool changer, we can deliver high volume, precision CNC manufacturing for our clients in specialized industries like photonics, labs, imaging, and electronics. Haas VF-4SS Highlights: High-speed spindle Fast rapids Super-speed side-mount tool changer More X- and Z-axis travel Made in the USA

OFFICE HOURS

- Mon - Fri

- -

- Sat - Sun

- Closed